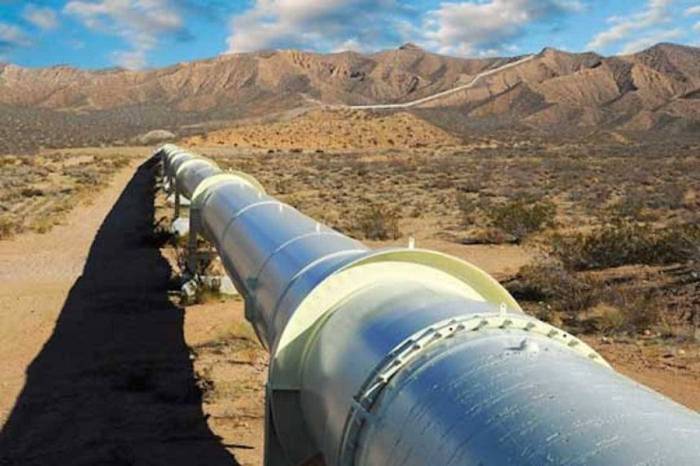

A pipeline used for the transport of crude oil – Pipelines used for the transport of crude oil play a pivotal role in the global energy industry, serving as the primary means of transporting vast quantities of this essential resource over long distances.

These pipelines, which can span thousands of kilometers, are meticulously designed and constructed to ensure the safe and efficient flow of crude oil from production sites to refineries and distribution centers.

1. Introduction: A Pipeline Used For The Transport Of Crude Oil

Pipelines play a critical role in the global energy industry, transporting vast quantities of crude oil from production sites to refineries and distribution centers. These pipelines provide a cost-effective and efficient means of transporting crude oil over long distances, enabling the efficient distribution of energy resources worldwide.

2. Types of Pipelines

Onshore Pipelines

Onshore pipelines are laid on land, traversing various terrains and geographical features. They are typically constructed using steel pipes with diameters ranging from a few inches to several feet, and can extend for hundreds or even thousands of kilometers.

Offshore Pipelines

Offshore pipelines are laid on the seabed, connecting offshore oil and gas fields to onshore processing facilities or transportation hubs. They are designed to withstand the harsh conditions of the marine environment, including high pressure, strong currents, and potential seabed hazards.

Subsea Pipelines, A pipeline used for the transport of crude oil

Subsea pipelines are a type of offshore pipeline that are buried beneath the seabed, providing added protection against external factors and potential damage. They are often used in deepwater environments or areas with sensitive marine ecosystems.

3. Design and Construction

Pipe Materials and Specifications

Crude oil pipelines are typically constructed using steel or composite materials. Steel pipelines offer high strength and durability, while composite pipelines provide resistance to corrosion and can be lighter in weight.

Pipeline Diameter and Length

The diameter and length of a pipeline are determined by the volume of crude oil to be transported, the distance to be covered, and the terrain or seabed conditions. Larger diameter pipelines can accommodate higher flow rates, while longer pipelines require more pumping stations to maintain pressure.

Pumping Stations and Pressure Management

Pumping stations are installed along the pipeline to maintain the necessary pressure for crude oil flow. The number and capacity of pumping stations are determined by the pipeline’s length, elevation changes, and the viscosity of the crude oil being transported.

4. Operation and Maintenance

Crude Oil Flow Rates and Pressure Monitoring

The flow rate and pressure of crude oil in the pipeline are continuously monitored to ensure efficient operation and prevent potential incidents. Advanced monitoring systems allow operators to remotely track pipeline conditions and make adjustments as needed.

Leak Detection and Prevention Systems

Pipelines are equipped with sophisticated leak detection systems that use sensors and algorithms to identify even the smallest leaks. These systems provide early warning, allowing operators to take immediate action to minimize environmental impact.

Pipeline Maintenance and Inspection Schedules

Regular maintenance and inspection are crucial for ensuring the integrity and longevity of crude oil pipelines. Inspections include visual checks, corrosion monitoring, and internal cleaning to remove deposits and maintain optimal flow.

5. Environmental Considerations

Land Use and Habitat Disruption

Pipeline construction can disrupt land use and habitat for wildlife, particularly in sensitive ecosystems. Environmental assessments are conducted to minimize impacts and mitigate potential harm to biodiversity.

Potential Oil Spills and Leaks

While pipelines are designed with safety measures, oil spills or leaks can occur due to unforeseen events or human error. Contingency plans and emergency response procedures are in place to minimize the impact of such incidents.

Mitigation Measures and Best Practices

Pipeline operators implement various mitigation measures to reduce environmental impacts, including erosion control, habitat restoration, and spill prevention programs. Best practices and industry standards are followed to minimize the environmental footprint of pipeline infrastructure.

Essential Questionnaire

What are the primary types of pipelines used for crude oil transport?

Onshore pipelines, offshore pipelines, and subsea pipelines are the three main types.

How are crude oil pipelines designed to withstand the harsh conditions they encounter?

Pipelines are constructed using robust materials, such as steel or polyethylene, and are equipped with protective coatings to resist corrosion and external damage.

What measures are in place to prevent and mitigate oil spills from pipelines?

Leak detection systems, regular inspections, and emergency response plans are implemented to minimize the risk of spills and ensure a prompt response in the event of an incident.