Delve into the world of Salem sump tube air vents, indispensable components in fluid management systems. These ingenious devices play a crucial role in ensuring efficient fluid flow and preventing air blockages, making them essential for a wide range of industrial and commercial applications.

Discover the types, materials, and applications of Salem sump tube air vents. Explore their advantages and potential drawbacks, ensuring you make informed decisions for your specific needs.

Salem Sump Tube Air Vent Basics

A Salem sump tube air vent is a medical device used during surgical procedures to allow air to enter the peritoneal cavity, the space within the abdomen that contains the organs.

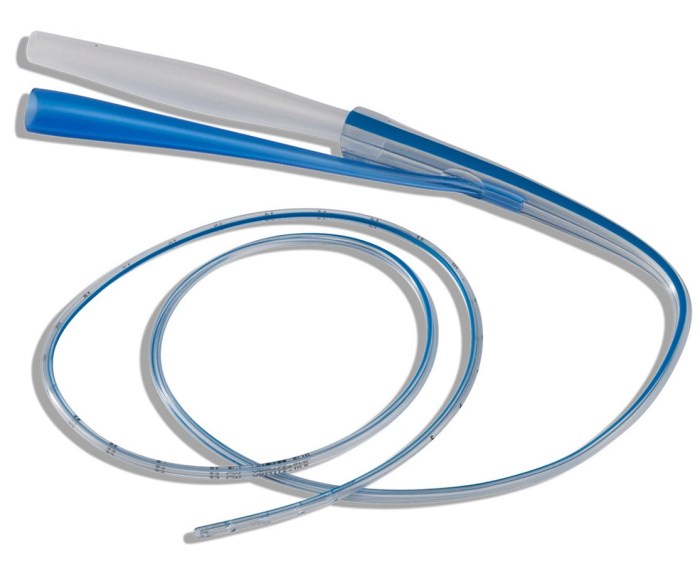

Salem sump tube air vents are typically made of a soft, flexible material, such as silicone or latex, and have a small hole at the end that allows air to enter. They are inserted into the peritoneal cavity through a small incision and are held in place with a suture.

Types of Salem Sump Tube Air Vents

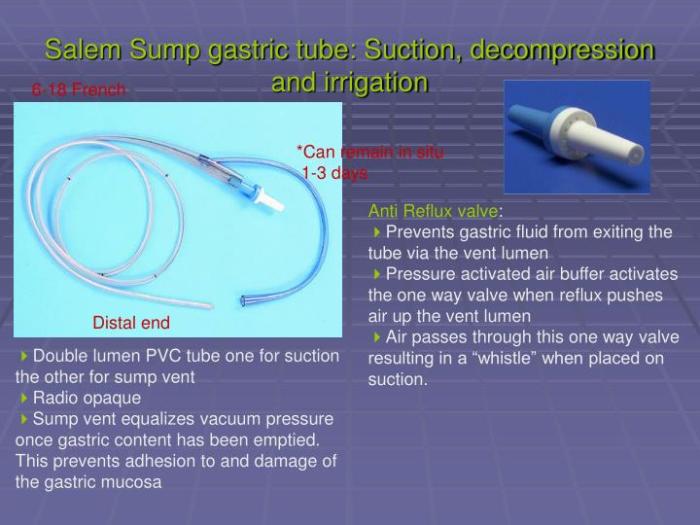

There are two main types of Salem sump tube air vents: open and closed.

- Open Salem sump tube air ventshave a hole at the end that is always open, allowing air to enter the peritoneal cavity at all times.

- Closed Salem sump tube air ventshave a hole that is covered by a flap or valve, which can be opened or closed to control the amount of air that enters the peritoneal cavity.

Materials Used in the Construction of Salem Sump Tube Air Vents

Salem sump tube air vents are typically made of a soft, flexible material, such as silicone or latex. These materials are biocompatible, meaning that they are not harmful to the body and will not cause an allergic reaction.

When it comes to the intricacies of salem sump tube air vent, finding reliable information can be challenging. Fortunately, relias ed rn a answers provides a comprehensive database of resources to address all your queries. Their expert insights and evidence-based guidance will empower you to tackle any aspect of salem sump tube air vent with confidence.

Installation and Maintenance

Proper installation and maintenance of Salem sump tube air vents are crucial for ensuring their optimal performance. This section will provide step-by-step instructions for installation, discuss the importance of regular maintenance and cleaning, and share troubleshooting tips for common issues.

Installation

Installing a Salem sump tube air vent involves the following steps:

- Locate the sump pump basin and identify the knockout plug on the side of the basin.

- Remove the knockout plug using a screwdriver or pliers.

- Insert the Salem sump tube air vent into the knockout hole and tighten the locknut to secure it.

- Connect the air vent hose to the air vent outlet and route it to the outside of the building.

Maintenance and Cleaning

Regular maintenance and cleaning of Salem sump tube air vents are essential to ensure proper airflow and prevent clogging. Here are some key steps to follow:

- Inspect the air vent and hose for any visible damage or blockages.

- Clean the air vent and hose with a mild detergent and water solution.

- Remove any debris or algae that may have accumulated inside the air vent.

- Rinse the air vent and hose thoroughly with clean water.

- Allow the air vent and hose to dry completely before reassembling.

Troubleshooting

If you encounter any issues with your Salem sump tube air vent, here are some common problems and troubleshooting tips:

- Air vent not working:Check if the air vent is clogged with debris or algae. Clean the air vent and hose as described above.

- Water leaking from the air vent:Tighten the locknut on the air vent to ensure a secure fit. Inspect the hose for any cracks or damage.

- Air vent making noise:This could indicate a loose locknut or a blockage in the air vent or hose. Tighten the locknut and clean the air vent and hose.

Advantages and Disadvantages

Salem sump tube air vents offer both benefits and drawbacks, depending on the specific application and installation requirements.

Advantages of using Salem sump tube air vents include:

- Effective moisture removal: Salem sump tube air vents are designed to efficiently remove moisture and condensation from enclosed spaces, reducing the risk of mold, mildew, and other moisture-related issues.

- Low maintenance: These air vents require minimal maintenance, typically only requiring occasional cleaning to ensure proper airflow.

- Versatile installation: Salem sump tube air vents can be installed in various locations, including attics, crawl spaces, and basements, making them suitable for a wide range of applications.

Disadvantages of using Salem sump tube air vents include:

- Limited airflow: Salem sump tube air vents may not provide sufficient airflow in certain applications, especially in larger or poorly ventilated spaces.

- Prone to clogging: The narrow tube design of Salem sump tube air vents can make them susceptible to clogging by dust, debris, or insects, which can reduce their effectiveness.

- Potential for freezing: In cold climates, the water in the sump tube can freeze, blocking airflow and potentially causing damage to the vent.

Benefits in Specific Applications

Salem sump tube air vents are particularly beneficial in applications where moisture control is crucial, such as:

- Attics: Salem sump tube air vents can help prevent moisture buildup in attics, which can damage insulation, roofing materials, and other components.

- Crawl spaces: These air vents can effectively remove moisture from crawl spaces, reducing the risk of mold and mildew growth and improving indoor air quality.

- Basements: Salem sump tube air vents can help ventilate basements, which are often prone to moisture problems, reducing musty odors and creating a healthier environment.

Applications and Use Cases

Salem sump tube air vents are widely used across various industries and applications. Their unique design and functionality make them an ideal choice for specific air venting requirements.

In the chemical industry, Salem sump tube air vents are employed in reactors, storage tanks, and other vessels to manage pressure and prevent the ingress of contaminants. They effectively release excess pressure while maintaining a sterile environment, ensuring the integrity of sensitive chemical processes.

Pharmaceutical Industry

- Salem sump tube air vents are crucial in the pharmaceutical industry for maintaining sterility in production facilities. They are used in cleanrooms, isolators, and other controlled environments to prevent contamination and ensure product quality.

- The vents effectively release pressure and maintain a positive airflow, preventing the ingress of contaminants and ensuring a sterile environment for pharmaceutical manufacturing.

Biotechnology Industry

- In the biotechnology industry, Salem sump tube air vents play a vital role in bioreactors and fermentation tanks. They provide controlled aeration and pressure management, essential for the growth and production of microorganisms.

- The vents facilitate the exchange of gases, allowing oxygen to enter and carbon dioxide to escape, while preventing contamination and maintaining a sterile environment.

Case Study: Pharmaceutical Manufacturing Facility

A leading pharmaceutical manufacturing facility implemented Salem sump tube air vents in its cleanrooms to enhance sterility and prevent contamination. The vents effectively maintained a positive airflow and prevented the ingress of particles, resulting in a significant reduction in product contamination rates.

Design and Construction

Salem sump tube air vents are specifically designed for use in drainage systems to prevent clogging and ensure proper air circulation. They feature a unique construction that allows for efficient air intake while preventing debris and water from entering the drainage system.

The key components of a Salem sump tube air vent include:

- Vent Cap:The vent cap is located at the top of the air vent and is designed to allow air to enter the system while preventing debris and water from entering.

- Vent Tube:The vent tube is a vertical pipe that connects the vent cap to the sump.

- Sump:The sump is a reservoir located at the bottom of the air vent that collects any water or debris that may enter the system.

The design and construction of Salem sump tube air vents are influenced by several factors, including:

- System Capacity:The size and capacity of the drainage system will determine the size and capacity of the air vent required.

- Location:The location of the air vent will also influence its design and construction. For example, air vents located in areas with high levels of debris may require additional protection.

li> Materials:The materials used to construct the air vent will also affect its design and construction. For example, air vents made from durable materials will be more resistant to corrosion and damage.

Standards and Regulations: Salem Sump Tube Air Vent

Adhering to industry standards and regulations is crucial for ensuring the safe and effective use of Salem sump tube air vents. These guidelines provide a framework for proper installation, maintenance, and operation, minimizing risks and ensuring optimal performance.

Key industry standards and regulations that apply to Salem sump tube air vents include:

ASTM F2368

- Standard Specification for Sump Tube Air Vents

- Establishes minimum performance requirements, material specifications, and testing procedures for sump tube air vents.

NFPA 96

- Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

- Provides guidance on the installation and use of sump tube air vents in commercial kitchens to prevent grease buildup and fire hazards.

UL 710

- Standard for Exhaust Hoods for Commercial Cooking Equipment

- Includes requirements for the installation and testing of sump tube air vents in commercial kitchen exhaust hoods.

IBC

- International Building Code

- May include provisions related to the use of sump tube air vents in certain building applications, such as commercial kitchens and industrial facilities.

Compliance with these standards and regulations helps ensure that Salem sump tube air vents are installed and maintained properly, minimizing the risk of grease fires, improving indoor air quality, and extending the lifespan of the equipment.

Resources for accessing these standards and regulations:

FAQ Resource

What is the purpose of a Salem sump tube air vent?

Salem sump tube air vents are designed to allow air to enter or escape a fluid system, preventing the formation of air pockets that can disrupt fluid flow and cause equipment damage.

What are the different types of Salem sump tube air vents?

Salem sump tube air vents come in various types, including in-line, elbow, and tee configurations, each suited for specific applications.

What materials are used in the construction of Salem sump tube air vents?

Salem sump tube air vents are typically made from durable materials such as stainless steel, brass, and PVC, ensuring resistance to corrosion and harsh chemicals.